Landworld's

pace of production has always been intense. In order to meet increasing global

demand and improve production efficiency, we recently decided to increase the

capacity of the factory.

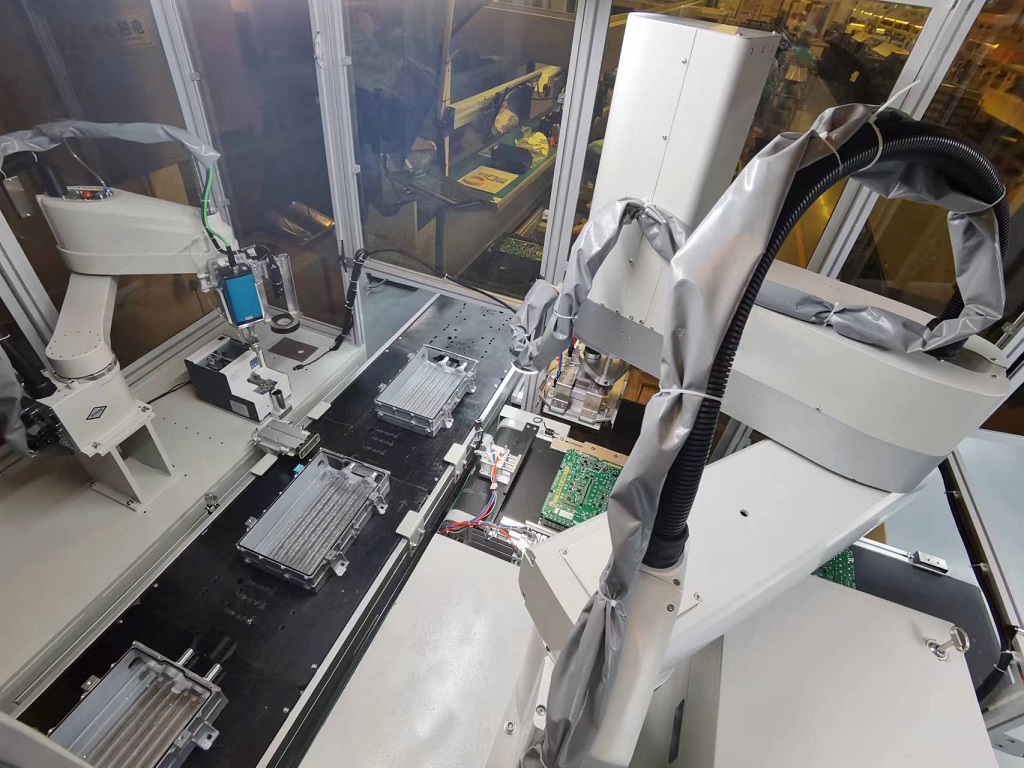

We upgraded the assembly line, increased the production capacity of the workshop, introduced automation equipment. The result of this retooling phase is a much-expanded operation that allows us to produce more on-board power supply products (DC/DC, On-board Charger, and integrated solutions), faster, while increasing automation and providing a more inviting work environment.

The most dramatic changes are to be found in assembly, where we’ve reduced the number of workers in favor of advanced robots that can lift work efficiency and reduce defective rate. Our new robots will be relieving humans of the most labor-intensive operation in the factory and reducing installation time by 30%.

Alongside the robots, we’ve built a production line with flexible production standards, relying on the intelligent manufacturing MES information system, which has realized the infrastructure and data transmission as well as the connection between equipment and system to meet the requirements of simultaneous production switching of multi category products at any time. Meanwhile, automated line that equipped MES system is laid out with room to grow so future capacity increases can take place with minimal disruption to existing operations.We also have introduced ESOP paperless operation in the core production link to reduce carbon dioxide emissions.

Facts and figures from the LANDWORLD Factory

• 1400 square meters of production line

• 5 assembly lines

• 200000+ sets capacity

• 9 sets automation equipment

Previous

Previous Next

Next Return

Return